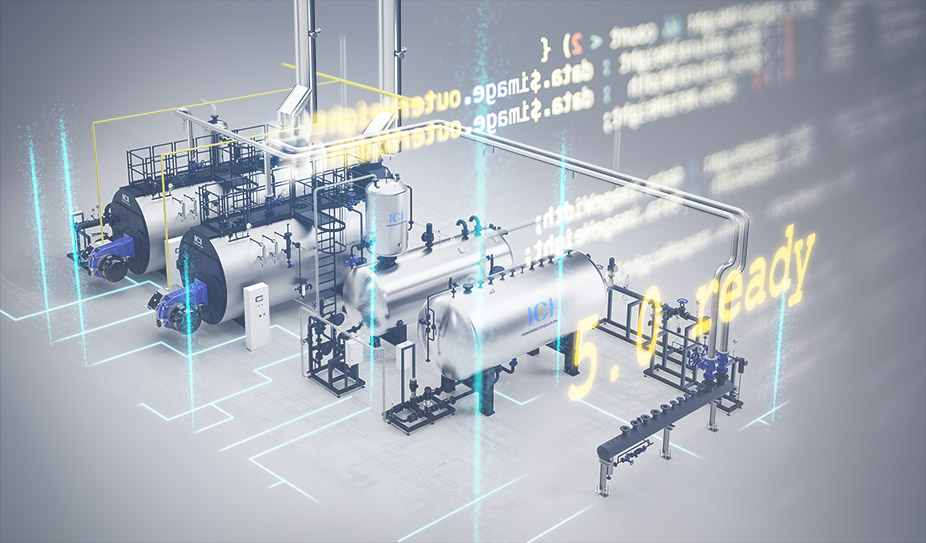

Maintain control of the entire system by setting and monitoring it

With our advanced remote management system, the heating plant can be connected to the production system in a 5.0 perspective, controlled remotely and monitored continuously 24 hours a day. This allows for perfect alignment of the required thermal load and the timely detection of any inefficiencies and anomalies.

What does all this translate into?

- Generate heat with maximum efficiency

- Have significant energy savings

- Distribute only the heat needed

- Reduce maintenance costs

- Reduce the power used

- Increase the lifespan of the system

- Reduce environmental impact

1. Generate heat with maximum efficiency

Boiler performance is essential to achieve good overall system efficiency. The reliability and quality of ICI Caldaie heat generators have been a benchmark for the market for over 50 years.

2. Have significant energy savings

Only the heat that is needed is produced, thus eliminating dispersion and waste.

Free heat inputs such as solar energy are optimised.

3. Distribute only the heat necessary

eterm control systems ensure that the carrier fluid is brought to the appropriate temperature and circulated correctly. Excessive flow rates and temperatures increase system losses.

4. Reduce maintenance costs

The eterm system allows operators to minimize and optimize interventions. The system features simplify interventions and allow diagnosis and correction of the configuration even remotely.

5. Reduce the power used

Reducing the requirement allows you to install less power, reducing costs, space and improving overall management performance.

6. Increase the lifespan of the system

By minimizing heat generation and the operation of circulation devices, thermal stress and wear of components are reduced.

7. Reduce environmental impact

As a result of energy saving, the production of combustion products that pollute the environment is reduced.