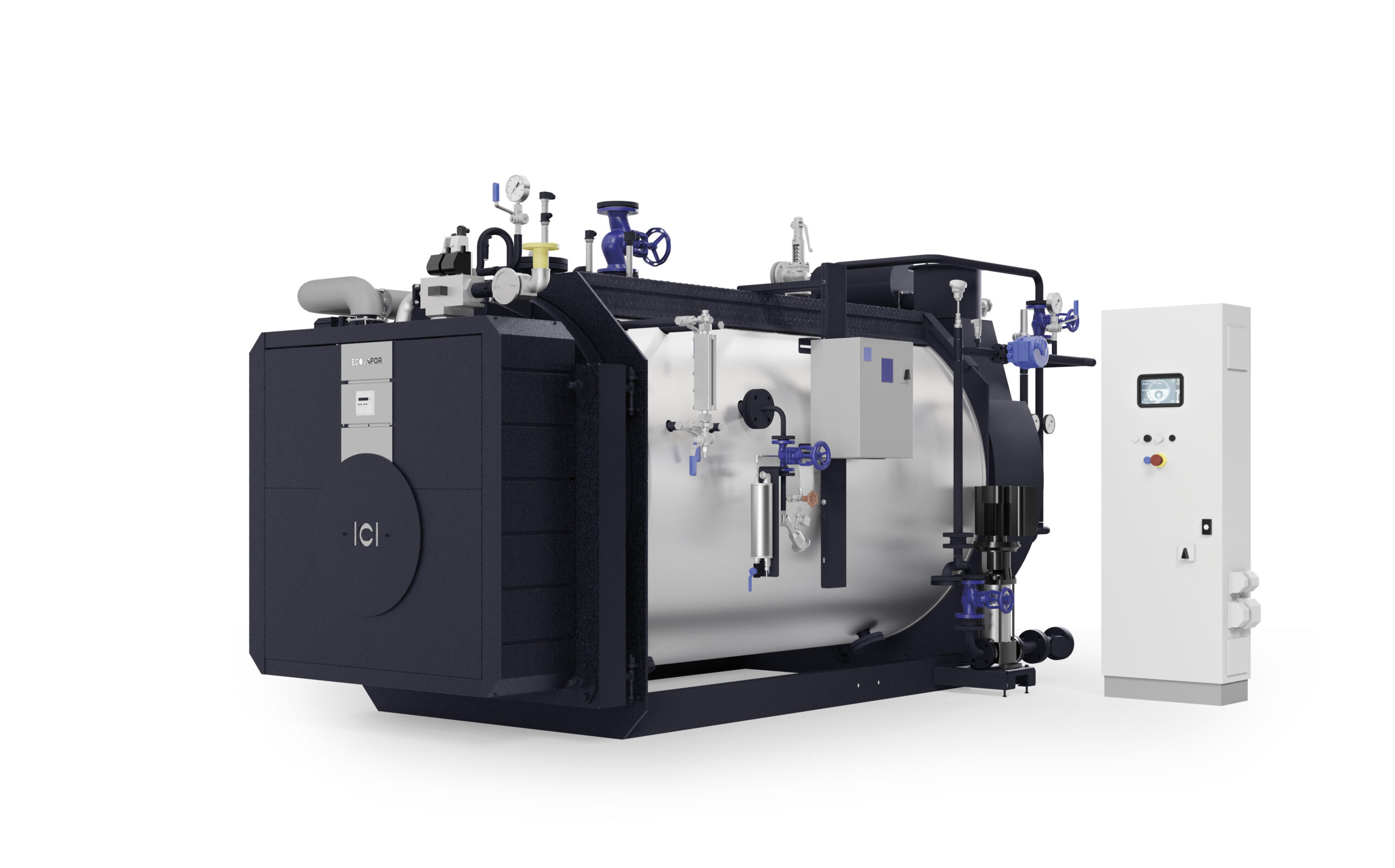

Thanks to the most advanced technologies on combustion, heat transfer and energy efficiency, ECOVAPOR ensures a very convenient cost of ownership combined to a very low environmental impact.

Home | Prodotti | Industrial Boilers | ECOVAPOR

Steam production: 1000 ÷ 3000 kg/h

Nominal power: 681 ÷ 2044 kW

Design pressure: 12 bar

Efficiency: > 95,0 %

Thanks to the most advanced technologies on combustion, heat transfer and energy efficiency, ECOVAPOR ensures a very convenient cost of ownership combined to a very low environmental impact.

The modulation ratio, inverters on the motors, fewer thermal losses and load adaptation all contribute to decrease of electrical energy and fuel consumptions with respect to a traditional boiler.

The innovative vector flame and vacuum combustion system completely integrated into the structure keeps NOx emissions below the most restrictive international legal limits.

Fuel and combustion air suction prevents dangerous flue gas leakages in the working environment.

Moving parts and complex electronic logics have been replaced by fixed systems.

ECOVAPOR is certified for unattended operation for 24 (ECS24 Model) or 72 consecutive hours (ECS72 Model), according to the latest European Standards.

ECOVAPOR adjustment and control system integrates control and adjustment functions, safety, connectivity and data logging of both the boiler and the combustion part.

Turnkey thermal power plants Our offer is your solution We design and build turnkey thermal power plants.Starting with...

Service SECTOR: Post-Vendita Service Through this service, the customer can request support from ICI Caldaie for personalized assistance.The...

For Personalized Support Service Level Agreement It is a customized contract that defines the services needed for the...

Service Service Once the installation has been completed, it is possible to request a test of the system...

Service Service Through this service the customer can agree with ICI a personalized Spare Parts List.The service allows...

Service Service ICI offers its customers a rental service for steam, hot water, superheated water and diathermic oil...

If you need further information, samples, a quote or advice for a project, please fill out the form below and we would be happy to help.

No documents available

To download the technical documentation you must be logged in.

EVOSTEAM is a three-pass steam boiler designed to offer high efficiency and adaptability to advanced industrial needs. Available...

Steam production: 1500 ÷ 10000 kg/h

Nominal power: 1020 ÷ 6826 kW

Design pressure: 12 or 15 bar

Efficiency: >90 %

Super-heated water boiler with fire tubes, waste heat recovery and monobloc type, compliant with the PED Directive 2014/68/...

Nominal power: 233 ÷ 17000 kW

Design pressure: 4,9 ÷ 12 bar

Hot water boiler with fire tubes, waste heat recovery and monobloc type, compliant with the PED Directive 2014/68/EU...

Nominal power: 3000 ÷ 25000 kW

Design pressure: 6 ÷ 25 bar

Thermal oil heater with water finned pipes, waste heat recovery and monobloc type, compliant with the PED Directive...

Nominal power: 116 ÷ 9300 kW

Design pressure: 10 bar

The SIXEN N range consists of monobloc reverse flame wet back fire tube steam boilers. This range is...

Steam production: 350 to 5000 kg / h

Nominal power: 238 ÷ 3407 kW

Design pressure: 12 or 15 bar

Efficiency: > 90.0%

The TNOX range includes three pass, wet back boilers with low thermal load in the combustion chamber (between...

Nominal power: 2500 ÷ 25000 kW

Design pressure: 6 bar

The waste-heat boilers of the WH range recover energy from hot flue gases as heat source without any...

Nominal power: 100 ÷ 20000 kW

Design pressure: from 1 to 25 bar

Clean indirect steam boiler easy to install thanks to duly sized components, mounted and connected at the factory...

Steam production: 160 ÷ 2750 kg/h

Nominal power: 115 ÷ 2054 kW

Design pressure: 6 bar

Instantaneous steam boiler – easy to install and user-friendly. Ideal for facilities such as laundries, it meets small...

Steam production: 20,3 ÷ 244,2 kg/h

Nominal power: 15 ÷ 180 kW

Design pressure: 4,5 bar