Context

Climate change is the result of greenhouse gas emissions and their consequent increase in concentration in the atmosphere. The greenhouse effect is quickly translating from an environmental problem to an economic and a social one.

For this reason, many countries, and Europe with the Horizon2020 program, are investing resources in the study of new processes that will reduce CO2 emission.

Designing cutting-edge technologies to convert CO2 produced in large industrial plants, into Dimethyl Ether (DME), an organic gas with high added value with characteristics similar to LPG and widely used in the chemical industry.

Project goals

Designing cutting-edge technologies to convert CO2 produced in large industrial plants, into Dimethyl Ether (DME), an organic gas with high added value with characteristics similar to LPG and widely used in the chemical industry.

Project steps

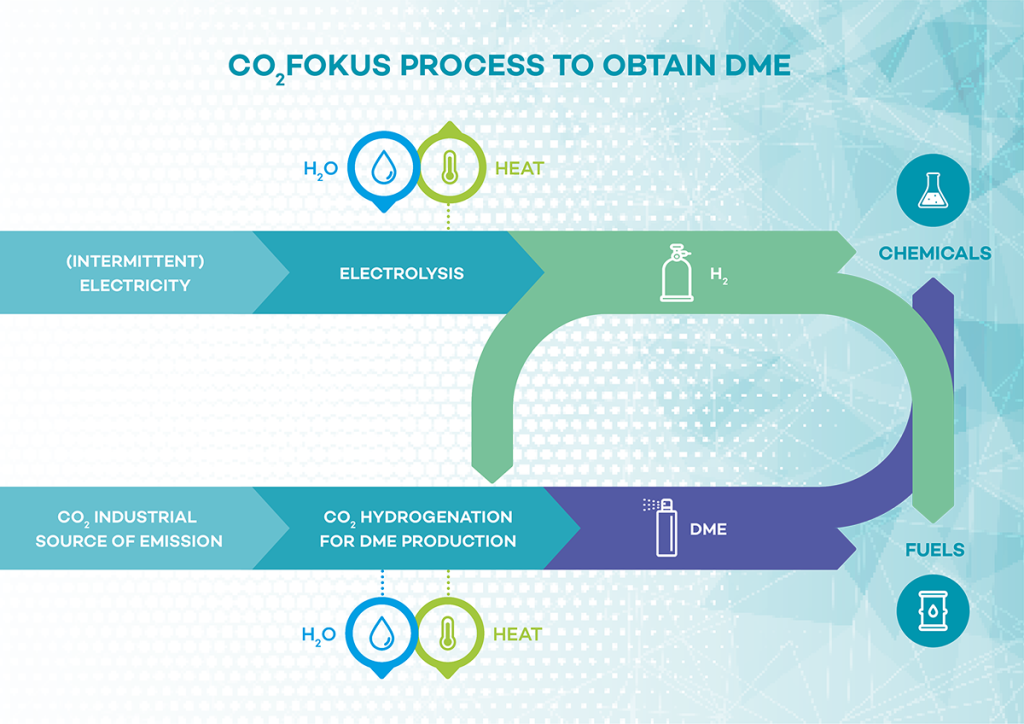

We currently produce DME by dehydrating methanol. The process requires 2 phases, a high level of energy, and substantial infrastructural investments. Part of the Co2fokus project will be to demonstrate the feasibility of directly-synthesized DME from CO2 and hydrogen.

This will be possible by exploiting a new multichannel reactor which will host the necessary catalytic and electrochemical chemical reactions.

The various components of the catalytic reactor will first be produced via 3D printing, tested in the laboratory and subsequently in the field.

The project’s steps are:

- Development of catalysts for the reactor: design and construction of highly sensitive and durable catalysts that ensure

greater efficiency and lower costs than those currently used. - Reactor development: Design of a structured multichannel reactor for the production of DME.

- Development of a solid oxide electrolyzer: Realization of an electrolyzer for the conversion of CO2 and H2O into a mixture

of CO and H2 necessary for the production of DME. - Industrialization: optimization and integration of the system’s production processes.

- Social, environmental and economic assessment: life cycle analysis for full impact assessment

of the new DME production line.

Ici Caldaie’s rule

In this ambitious project, ICI Caldaie is responsible for all aspects related to systems integration. Starting from the evaluation and development of the various components necessary, their correct functioning, and management, as well as the overall safety and control logic system. We have been tasked also to supervise the fluids and gases parameters such as flow rates, temperatures, and pressure.