Home | Accessori Caldaia | All Boilers | Eterm Easy Manager Panel

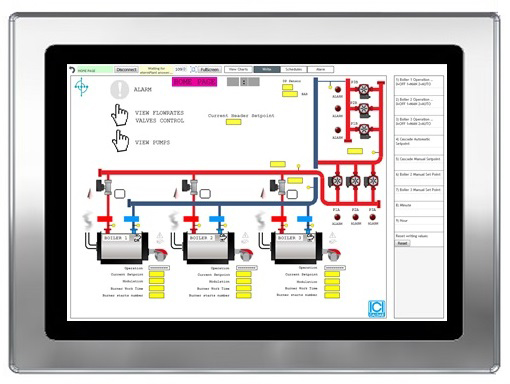

Control panel with 15” touch screen for a personalised view of the heating plant room (synoptic diagram). The panel must be connected via bus to the boiler Eterm control panels and to Nereix devices (plant and/flat metering devices) From the graphic panel it is possible to: - view the instantaneous values of temperature, operating status, modulation percentage values, alarms, etc. - send starting, stopping, forcing, setpoint and other types of commands - view graphs of the saved variables - export images of the graphs and Excel tables of the log data - view the alarm log The ModBus RS485 port (2 wires) is available for only one of the following options: 1- ModBus Master ModBus slave device management, i.e. the ability to manage other devices featuring the same interface from the graphic page. (ICI Caldaie reserves the right to check the compatibility of the devices) 2-ModBus Slave Conversion of all eterm parameters, both in reading and in writing mode, in ModBus protocol for external supervision systems provided with such interface. The maximum number of parameters that can be provided is 500 and they can be chosen by the customer based on the system. The control panel is provided with a device for Internet connection: the type of preferred connection determines the type of device installed inside the panel.

The SIXEN N range consists of monobloc reverse flame wet back fire tube steam boilers. This range is...

Steam production: 350 to 5000 kg / h

Nominal power: 238 ÷ 3407 kW

Design pressure: 12 or 15 bar

Efficiency: > 90.0%

The TNOX range includes three pass, wet back boilers with low thermal load in the combustion chamber (between...

Nominal power: 2500 ÷ 25000 kW

Design pressure: 6 bar

The waste-heat boilers of the WH range recover energy from hot flue gases as heat source without any...

Nominal power: 100 ÷ 20000 kW

Design pressure: from 1 to 25 bar

Clean indirect steam boiler easy to install thanks to duly sized components, mounted and connected at the factory...

Steam production: 160 ÷ 2750 kg/h

Nominal power: 115 ÷ 2054 kW

Design pressure: 6 bar

Instantaneous steam boiler – easy to install and user-friendly. Ideal for facilities such as laundries, it meets small...

Steam production: 20,3 ÷ 244,2 kg/h

Nominal power: 15 ÷ 180 kW

Design pressure: 4,5 bar

Instantaneous reverse flame fire tube steam boiler, completely automatic and with high efficiency. Low water content and reduced...

Steam production: 50 ÷ 300 kg/h

Nominal power: 31,7 ÷ 209,2 kW

Design pressure: 5 bar

Efficiency: > 91,0 %

Monobloc low-pressure reverse flame wet back steam boiler, suitable for liquid or gaseous fuels., It is a brand-new...

Steam production: 100 ÷ 3000 kg/h

Nominal power: 69,8 ÷ 2035 kW

Design pressure: 0,98 o 0,5 bar

Efficiency: > 91,0 %

The TReVAPOR range encompasses steam generators designed to exceed today’s standards in terms of efficiency and low polluting...

Steam production: 1200 ÷ 6500 kg/h

Nominal power: 818 ÷ 4770 kW

Design pressure: 12 bar

Efficiency: 90,5 %

The GX range features outstanding monobloc steam generators, designed to give maximum reliability and durability. All models have...

Steam production: 1700 ÷ 32000 kg/h

Nominal power: 1163 ÷ 17442 kW

Design pressure: 12 or 15 bar

Efficiency: 90,0 %

To download the technical documentation you must be logged in.

Nessun documento disponibile

No documents available

No documents available