Context

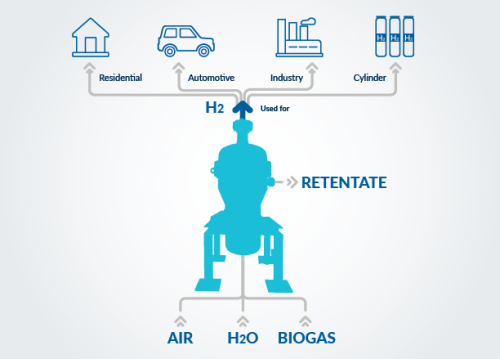

Biogas is a gas mix consisting mainly of methane (up to 60%), carbon dioxide, and nitrogen in small percentages. It’s the natural product of the decomposition of organic waste and can be recovered and used to produce energy.

Project goals

To design and develop a new prototype reactor and its utilisation in a biogas plant capable to produce hydrogen and separate it from the remaining gases.

Currently, on the market, there are already reactors that through different steps are able to produce hydrogen from biogas, but there are no systems that simultaneously produce and separate it.

The combination of hydrogen production and separation thanks to the use of the Bionico process, allows us to achieve an overall theoretical efficiency of 72%. An increase of 20% percentage points compared to the values normally obtained with a traditional process of 52%.

In addition to increasing efficiency, Bionico has contributed to the simplification of components, reducing the costs associated with the system’s construction.

Project steps

- Development of a new highly active reforming catalyst for the production of hydrogen from biogas with different compositions.

- Development of tubular membranes for selective hydrogen biogas

- Production of a first prototype reactor for laboratory tests

- Production of the second prototype for installation on the site dedicated to the production of biogas

- Installation and integration of the reactor in the production site and start of the test phase.

ICI’s rule

ICI designed and built the heart of the project: the reactor where we installed the membranes for the separation of pure hydrogen. The membranes, developed by TUE (Eindhoven University of Technology) and TECNALIA, are buried in a gas mixture formed by biogas, steam, air, catalysts, and reaction products.